We develop our products together with our customers to meet their evolving needs

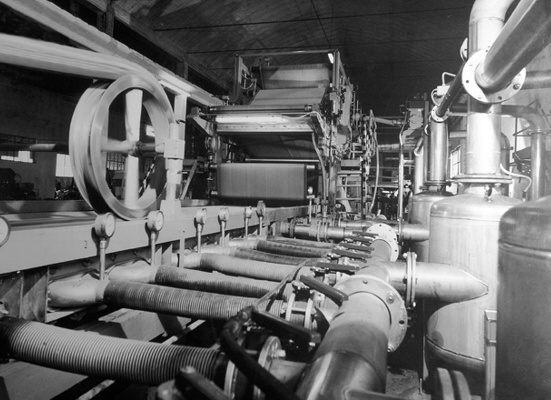

Once a leather tannery, Valle Esina made the choice in 1968 to focus on the recovery and recycling of industrial waste and transformed itself into a producer of regenerated leather.

From that pioneering choice, it has been constantly growing by implementing technologies and systems and constantly developing new products in line with the needs of the market and customers, carving out a leading role in Italy and abroad.

The entry into the fiberboard market is more recent with the starting of the production of a line with unique characteristics that allow to produce items, such as Tallonit and Glamour, capable of differentiating themselves from the competition.

The daily challenge is to satisfy and sometimes anticipate the evolving needs of our customers, guaranteeing the quality of work of our coworkers, while respecting the environment.

“Nothing is created, nothing is destroyed, everything is transformed”

Nothing confirms Antoine Lavoisier’s well-known principle like regenerated leather: what was waste becomes excellent raw material, a fundamental resource for the footwear, leather goods, objects and furniture industries.

The best substitute for natural leather has come to equal many of its intrinsic characteristics, but at lower costs and with respect for the environment.

Constant research, the mastery of our specialists and technological development have made regenerated leather by Valle Esina a point of reference in the sector for about half a century.

Fibreboard is obtained from recovery fibers and is itself recyclable.

Decades of experience and a propensity for innovation have allowed us to develop high quality products through the use of raw materials or those coming from paper mill by-products and from the recovery of processing waste.

Our fiberboard combines respect for the environment with the highest physical-mechanical characteristics.

The main uses are in the footwear sector, where there is absolute excellence in the creation of heel cups and insoles; thanks to its versatility and low cost it is now also used in the furniture and automotive sectors.